Since I posted

part 1 of the M2080 recovery failure report I have been in contact with Jeff Garvey at electricmatch.com. He's been very patient while I worked through his requested testing and here's what I emailed him today in its entirety:

*****************************************************************

Good afternoon, Jeff.

I just completed three phases of testing, fired a total of six M-teks with 7' leads, and added some knowledge but I still lack water-tight conclusions. As such I defer to your judgment on whether any form of warranty replacement is merited. I will post a version of this report to my

blog and append the

previous entry with a less certain conclusion in an addendum.

Thanks for your patience while I worked through this.

=G=

Executive Summary

While I cannot know if the impact damage of the previously failed recovery changed the ARTS2 altimeter, battery/ies, and/or initiators in question I have concluded that:

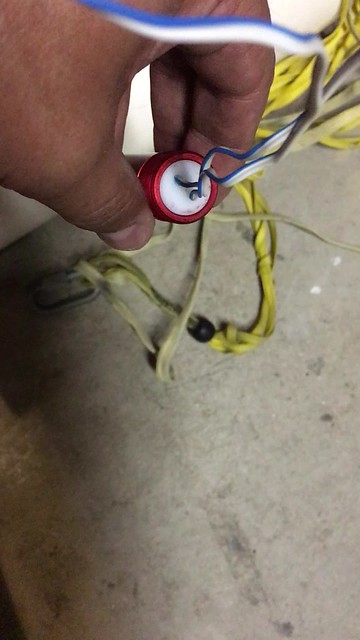

- Both initiators connected to the low-altitude CO2 system measured high and well out of spec in post-mortem testing (3.5 and 4.1V, respectively). None of the initiators sampled from the same two boxes measured anywhere near that high. It seems unlikely that both were outliers in light of the population data so it's possible that the flight impact and/or post-mortem extraction might have changed their resistances somehow.

- Altimeter one, a previously reliable Featherweight Raven 2, likely functioned as expected during the flight so the failure to actuate the CO2 ejection system at ~800 feet AGL remains a mystery. After the impact a component separated from the board and that's the likely cause of its inability to fire initiators in test mode.

- I have [linked to] the Raven2's acceleration, current, and main/apogee voltage graph and it suspiciously cuts off at about 29 seconds into the flight. It appears that the altimeter fired the apogee channel successfully and was in the process of recharging the capacitor when the data cuts off. To my knowledge this has never happened before with Featherweight altimeters so it could have been impact damage to the memory, a battery failure, or other unknown factor.

- Altimeter 2, a Loki Research ARTS2, was unable to fire even nominally resistive M-tek initiators with a fresh 9V battery in single-battery mode. When I switched to the two-battery configuration both the apogee and main channels fired as expected. This leads me to think that this copy of the altimeter, unlike my previous copy, is incapable of firing initiators in single-battery mode.

So I learned something about this particular ARTS2 today but its failure in single-battery mode serves to underscore the prior recovery reliability of the Raven 2 altimeter. In every case I can recall the Raven 2 operated effectively solo with the ARTS2 as failed backup in single-battery mode (but I was able to download seemingly accurate flight data from the ARTS2 after impact). I think that's all I can conclude from this post-mortem.

Experiments and Conclusions

Part 1 - Initiator resistances (all in Ohms) as measured with an

MN36 Autoranging Multimeter:

Box M1 - Box of (originally) 40 M-tek initiators with 7' leads purchased from

electricmatch.com

1.5

1.3

1.4

1.6

1.2

1.6

1.3

1.4

1.3

1.3

Box M2 - Box of 40 M-tek initiators with 7' leads purchased from

electricmatch.com

1.5

1.6

1.7

1.7

1.9

1.4

1.6

1.7

1.5

1.3

J D.R. - J-teks with 3' leads purchased from a third party solely for use in rocketry

1.8

1.9

2.3

3.0

1.7

J1 - J-teks with 3' leads purchased from a third party solely for use in rocketry

1.4

1.4

1.6

1.4

1.5

J2 - J-teks with 3' leads purchased from a third party solely for use in rocketry

1.4

1.4

1.5

1.5

1.5

Conclusion: With the exception of one J-tek at 1.2 Ohm all measure high relative to the spec.

*****************************************************************

Part 2 - 7/10/16 - Altimeter tests

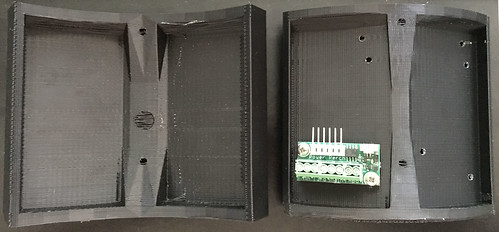

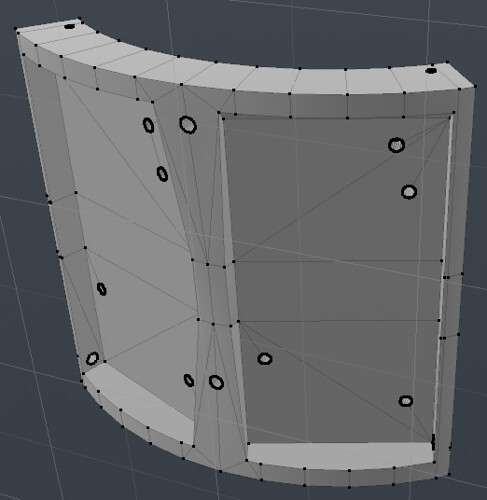

ARTS2 test (used in M2080 flight with failed recovery)

9V battery voltage - 9.43V, single-battery mode

M-Tek box 1 = 1.7 Ohm match (second highest measured resistance)

Connected to software, fired main twice, but the match did not fire.

Switched to apogee, fired it twice, but the match did not fire.

Connected it directly to 9V battery and the match fired.

Software not firing channels in test mode so... ARTS2 dead after hitting ground? Before? [see conclusions from part 3 below]

Raven2 test (used in M2080 flight with failed recovery)

Freshly charge LiPo battery

M-tek box 1 = 1.9 Ohm match for main (highest measured resistance) and 1.7 Ohm for Apogee connected simultaneously.

Ran the launch sequence twice but neither match fired (apogee/main)

Raven3 test (control)

Would not initialize the test for some reason even with a fresh battery. After some research on the inter webs... It turns out that the Raven3 needs at least 3.85V at startup to initialize properly. This results in 4 high beeps then one low beep at startup. Once I used a new and freshly charged LiPo then even the 3.0 Ohm initiators fired properly. (I also learned that the altimeter can be powered up in any orientation and then moved to long-axis-vertical for flight readiness without powering down first.)

Raven1 test (control)

Using battery from last fight without refreshing the charge

Test initialized correctly and I watched as both the apogee and main matches fired on time from the sim. (flight counter 14)

*****************************************************************

Part 3 - 7/31/16 - Explore the ARTS2 altimeter further

After the first test session on 7/10 I realized that the ARTS2 itself might not be working. Since the unit has already impacted the ground I can never know if it was defective (in terms of firing initiators) before the M2080 flight. I suppose it could have been defective but I never saw issues because there was always a Raven running independently next to it.

Today I'll try the following tests with the ARTS2:

- Single battery with lower resistance M-teks (1.3 and 1.4 Ohm, respectively).

- Dual battery with the same lower resistance M-teks (assuming they don't first in the first test).

- If neither test succeeds then I'll leave the board configured as in test 2 but swap in two J-teks from my stash and try again.

Test 1:

9V battery voltage, board and pyro power: 9.60V

Apogee channel: 1.3 Ohm initiator

Main channel: 1.4 Ohm initiator

Setup: beeps on power-up meaning both initiators were recognized. First attempt with board horizontal:

- Apogee: No fire

- Main: No fire

Switching the board to vertical:

- Apogee: No fire

- Main: No fire

Powering off the board and powering up vertically, chirp test OK:

- Apogee: No fire

- Main: No fire

Conclusion 1: In its current, post-impact state this ARTS 2 would not fire even with lower resistance initiators using a fresh, tested 9V battery.

Test 2:

9V battery voltage, board power: now 9.37V

9V battery voltage, pyro power: 9.63

Apogee channel: 1.3 Ohm initiator

Main channel: 1.4 Ohm initiator

Setup: Hooked up pyro battery, switched board to 2-battery config. Held board vertically on power-up and got the expected three beeps.

- Apogee: FIRED!

- Main: FIRED!

Conclusion 2: Both channels fired correctly in the board 2-battery configuration. I'm not certain but I don't think I've ever flown this ARTS2 solo and have always used it as a backup on two-altimeter flights primarily for motor performance and CD estimation data.