Some of you know that I've been dabbling in 3D printing for three-ish years. I ceaselessly admire the astonishing progress of garage-based hardware hackers using intellectual property from patents that have expired in recent years. It appears that the masses using democratized technology continue to move far faster than the corporations that developed the IP in the first place!! One new startup,

3D Printer Works, arose from a successfully funded Kickstarter campaign. I like their style and recently ordered their first product,

The CreatorBot 3D, for home use:

And yes of course I upgraded to the pro package with dual extruders, a heated glass build platform, acrylic enclosure to prevent drafts, and the

Raspberry PI with

OctoPrint to enable WiFi printing. Who wouldn't?!

With a nearly unparalleled prosumer build volume of 2,592 in

3 and 1 ft. x 1 ft build plate I decided that my first home project would have to be a V2 with a 24mm motor mount to take the full range of

Pro24 reloads. This is the first rocket I've attempted to design in my go-to 3D package,

Modo, and I'm very pleased with the initial version. I started with

V2 scale profile images from the interwebs and used them as background images in Modo. I then added a cylinder and adapted the cross-sectional hoops to conform to the airframe shape. I added edge loops at the fin root locations and extruded the fins directly out from the airframe. The entire model below is previewed in

Catmull-Clark Subdivision mode for maximum smoothness and that's the format I'll use to export the .stl files bound for equivalently smooth 3D printing:

That black feature in the center wireframe is a hypothetical Pro24 6GXL casing as a worst case motor length. While CTI presently offers only 1, 2, 3, and 6G casings in Pro24 I do see 4, 5, and 6XL on both David Reese's

Wildman West page and

CTI's page so I'll assume they're forthcoming some day soon. I still need to add features like the nosecone shoulder, shock cord mounts, and rail guide(s) but the exterior form exceeds my expectations and took only about 2 hours to complete. I also used Modo's powerful and astonishingly versatile

bevel tool to build both the vented motor mount and the interior walls of the airframe in a single operation set:

I plan to print with

ABS that flows and extrudes reliably at 230˚C but its glass transition temperature hovers around 105˚C (221˚F).

NFPA specifies a maximum casing temperature of 200˚C for 160 N•s or smaller so this could be an issue. ;) As such I think that venting the motor tube inside the airframe will decrease the likelihood of structural failure due to motor casing heat. If I observe melt damage I can always add exterior vents to the airframe and maybe I'll make them whistle while I'm at it. For the first flight I'm just planning to use two diametrically opposed, wide-head wood screws and perhaps washers for motor retention. Here's a top view showing the virtual 6XL casing in it's vented motor mount:

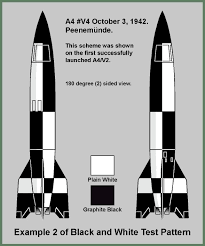

Once the model is finalized I also want to cleave it into pieces such that it can be printed in black and white using the dual extruders and according to the scale painting pattern so no painting will be required (and you know I LOVE painting!):

This first design will be 3" in diameter and 24.5" long. At the limit I should be able to design and print a roughly 10" diameter V2 in four vertical segments. More on this soon as my printer should arrive in the next two weeks. Yay, 3Dp!

Addendum: The site

3DPrint.com recently published this

article on

Steve Jurvetson who's advocating 3D printing for hobby rocketry for many good reasons. He also gives a genial introduction to rocketry and finishes with some cool SpaceX stuff. The revolution will be webcast!!