Rocket motor power designations allowed in California range from 1/4A through M with an 'A' motor yielding a maximum of 2.5 N•s of total impulse (the area under the thrust/time curve). Each successive letter is a maximum of double the previous letter and here's a handy

motor letter range chart. The biggest motor one can typically buy in a hobby store is a 120 N•s 'G' motor and motors above that impulse are designated as "high power" and their certification and use are regulated by organizations like

Tripoli,

NAR, and

CAR.

A typical motor is specified by a code including the following: [letter designating maximum total impulse][average thrust in Newtons (N)]-[time delay between motor burnout and parachute ejection]. For instance my favorite motor is an

Aerotech K1100-14. The 'K' denotes a total impulse of 1500 N•s (between 1280.1-2560 N•s). The 1100 is the average thrust in newtons and this equals ~242 pounds of force! This particular motor waits for 14 seconds after burnout before ejecting the parachute. Other delay options include 6, 10, & 18 seconds. Sometimes a motor has a 'P' in place of a time delay and this means the motor is Plugged and requires electronic timing and ejection actuation. [Ejectuation!?]

US rockets has proposed an improvement to this nomenclature that adds the exact total impulse number before the letter denoting impulse class. In this revised scheme the motor above would be called 1500K1100-14. It's a bit longer but as motor classes increase the range of total impulses grows geometrically. It also allows one to quickly estimate burn time by dividing total impulse by average thrust (1500 N•s/1100 N = 1.4 s). Unfortunately this nomenclature has not caught on and we're largely stuck with the antiquated scheme. I'll go ahead and use the new nomenclature because... it's my blog!

•

Level 1 certification requires that one fly an H- or I-class motor and get the rocket back in ready-to-fly condition. As a Tripoli member I certified level 1 in 2000 using an

Aerotech 240H242-10.

•

Level 2 begins with a 50 question, multiple choice test before flying a J, K, or L motor and retrieving the rocket intact. Half of the questions are

technical and half are on

safety. I scored 100% on my exam and successfully flew an

Aerotech 1280J415-14 in 2001 to earn level 2:

•

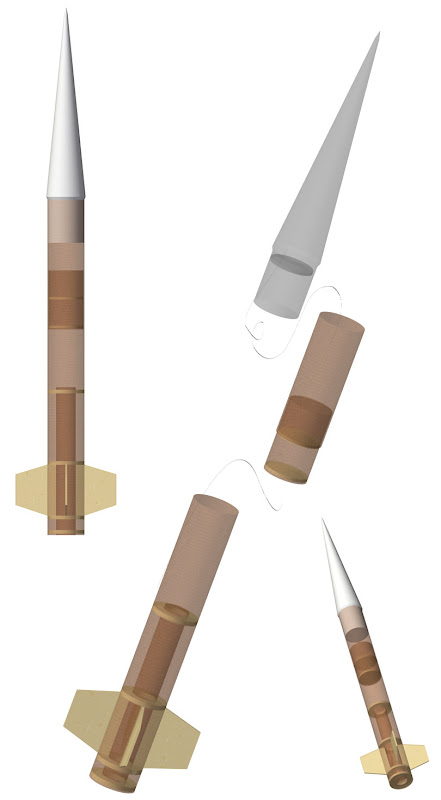

Level 3 requires that one create a ton of documentation on a planned M, N, or O flight and work with two Technical Advisory Panel members who have already earned their level 3 certs. Once all the pre-work is complete and the rocket is built then one flies an M motor and, upon successful retrieval, is awarded level 3 certification.

I plan to attempt my level 3 certification flight on June 7th, 2008 at the

Plaster City launch site in the desert East of San Diego. I've been advised to apply the K.I.S.S concept (Keep It Simple, Stupid) to my level 3 so I'm going to fly the smallest M motor the

5417M1297-P.

Please

contact me if you'd like to attend and/or help with photo and video documentation. Stay tuned for more updates as I step through the process, build, and flight.